Lean Processes

Lean is a methodology or approach to doing business that focuses on the elimination of waste and increasing value to the customer.

Value is determined by the customer and must meet three criteria to be value add for a customer. The three criteria are the following:

- The customer is willing to pay for it.

- Done right the first time.

- Directly transforms the product or service provided.

A key question in Lean is asking “What problem are you trying to solve?” Then you determine what tool or combination of tools you need to address the problem, the waste in your process.

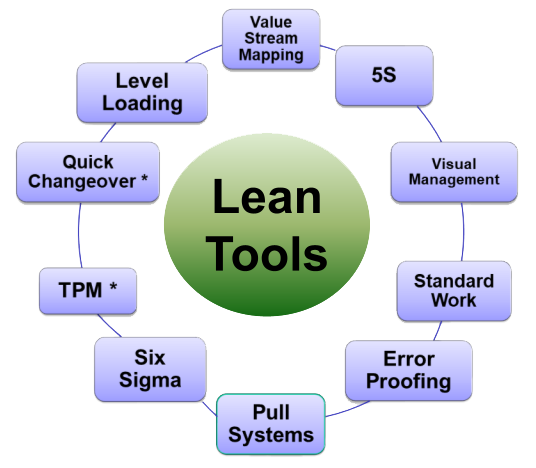

The tools below are common tools used in the implementation of a Lean strategy in an office, service, assembly, or manufacturing environment.

Historically, most lean efforts have focused on the assembly and manufacturing environments, but Lean is just as applicable in an office or service environment.

The Lean journey starts by using the lean tools of 5S and Visual Management. These tools help you create a high performing workspace. Everything has a place and everything in its place while using visuals for obvious detection of something out of place.

5S and Visual Management are followed by the development of Standard Work. Standard Work takes variation out of a process. The team utilizes metrics to determine the best-known way to perform their tasks today. As innovative ideas for improvement are identified a structured approach is utilized for changing standard work.

Once the foundational tools are implemented then you Map the Value Stream. Value Stream Mapping looks at your processes from order to cash and implements the following concepts:

- Flow, one piece or the smallest quantity that makes sense.

- Removal of Waste in the Value Stream

- Pull to minimize WIP & priming the line if applicable tominimize waiting of employees at the start of day.

- Balancing the work to Takt.

- Pull to Takt

When Lean concepts are employed, you will have minimized WIP & Finished Goods, and done so with the correct number of resources to perform the work.

Lean is a growth strategy. As you remove waste from the process and free up resources, you can use those resources to grow the top line without proportionally growing expenses, which results in increased profitability. Let Experience on Demand assist you in increasing your businesses profitability through the implementation of Lean.

For more information contact:

Karen Broyles at (636) 734-1786 or karen.broyles@experience-on-demand.com