By, Ray Scott – Senior Partner

Your inventory is a lot like Audrey II, the man-eating plant in Little Shop of Horrors – it can get out of control pretty quickly, and can consume your cash if you are not careful. There are some “big company” tactics that smaller companies can employ to help you tame the beast – resulting in improved customer service, positive cash flow, and increased profitability.

Businesses of any size and type can benefit from these proven inventory control methods:

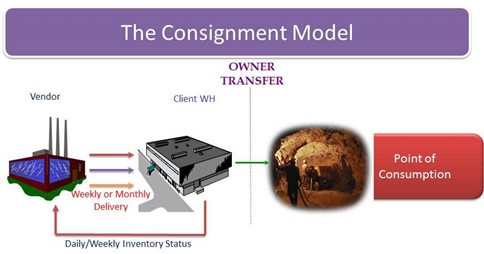

Consignment Inventory Model – Title Transfers When Item is Consumed

CONSIGNMENT INVENTORY

Material is physically at your location, but the supplier still has ownership of the items. This can be retail items, as well as items used in manufacturing or service. You pay for the goods as you use or sell them. Generally, since you physically control the inventory, you will be responsible for any damage or loss. The advantage to your company is that you don’t tie up your cash for an extended period of time. Having the material already on hand also helps shorten lead times, which can improve customer satisfaction. Consignment is also appropriate for service items or spares that are used infrequently, but which you need to have on hand. The supplier will audit the consignment stock at your location on a periodic basis to ensure that all usage is being properly reported and invoiced.

Watch out for: There is usually a time limit of 60 to 90 days where the items have to be taken – or you will be billed for them at the end of that time. You should also make sure that you clearly segregate any consignment inventory from inventory you have already purchased.

VMI Stocks in Store

VENDOR MANAGED INVENTORY

Here, the supplier takes over restocking of items as they are needed – think the snacks at the convenience store counters. Many retail outlets, such as grocery stores, also have suppliers stock shelves for items such as liquor, soda, or snack foods. You pay for the items as they are received, but the burden of managing the stock is taken on by the vendor; the supplier will determine when to restock and what quantity to replenish. This allows you to focus on higher value items that require more time and attention, while still maintaining stock on other items.

Watch out for: Some suppliers may try to overstock you at the end of the month or quarter in order to meet their sales goals. To avoid this unwanted inventory, have a clear upper limit on the amount of each item that can be on hand. Other important terms will include any minimum stocking levels; how often the quantity on hand is reviewed; whether the review is physically at your location or relies on electronic perpetual inventory records, and the lead time to replenish your stock after the review.

Simple Two-Bin System Using Barcode Scanning

VISUAL REPLENISHMENT

A simple system with two bins for each item works well for goods sold or used on a regular basis. To start the system, you stock two bins of the part and use them out of one bin at a time. When the first bin is empty, it is a signal to replenish, usually by the amount held in the bin. While the item is being replenished, you use out of the second bin. This limits the amount of inventory on hand, assuming you have sized the bins appropriately. This visual system is easy to manage and should help availability of the item. In some cases, a bar code label on the empty bin is scanned to signal the need for more stock from a storeroom or a supplier.

Watch out for: The second bin must have enough stock to cover the full replenishment time, plus a little safety stock, or you may run out. Also, assign responsibility to look for empty bins every day; make sure everyone understands that you must use up one bin before starting to pull from the second bin; and review usage on a regular basis. If you are constantly replenishing the bins, you may need a larger quantity in each; if there is a long time between replenishments, you may be able to reduce the inventory held in the bins.

NEED MORE INFORMATION?

There are other tactics that can help you right-size your inventory, regardless of the size of your organization. If you are interested in exploring ways to minimize your inventory investment while maintaining good service levels, contact Ray Scott at 314-304-8070 or ray.scott@experience-on-demand.com.